Meat(less) marvels: How Science is Changing the Way We Eat

A study of the meat market has determined that in 2040 only 40 % of the meat products consumed globally will actually be made from conventional meat. What will they be made of instead? There are two basic alternatives: Vegan meat replacements and cultured meat.

Marvelous Taste: Fermentation does the Trick

Soy milk, faux or fake cheese, insect burgers, vegan fish, and meatless schnitzel. They are all products that imitate animal-based food so that when we omnivores eat them to protect our health and the planet, we don't miss the taste of the original.

But how can you make a blob of white non-dairy matter made from faba beans, for example, taste like cheese and not like beans?

Flavor chemistry is the answer.

Flavor chemists at the University of Hohenheim make use of club fungi, also called basidiomycetes, to change the off-flavor taste of plant-based food products. The process is called fermentation.

Club fungi can produce specialized proteins like mycoprotein that can break down larger proteins into smaller pieces called amino acids. The breakdown of proteins by club fungi contributes to the development of flavors during fermentation. Sometimes, other microorganisms present during fermentation can further process the amino acids, adding to the overall flavor of the final product.

- Fermented micro algae can become a replacement for fish.

- Fermented spices are used to give meat substitutes a savory taste.

- Fermented pea or bean protein can get rid of the off-flavor of peas and beans in meat substitutes.

And there are even more advantages of fermentation:

Plant-based food often doesn't contain all the necessary macro- and micronutrients to the same extent as animal-based food. The club fungi's mycoprotein is able to raise the protein level of plant-based products and turn them into delicious AND healthy alternatives.

The fungi used to produce the mycoprotein are grown in bioreactors, so there’s no need for land-intensive agriculture.

The mycoprotein naturally creates a fibrous texture in the substitute product whereas plant-based alternatives have to go through an elaborate process of extrusion to get there.

The origins of fungal fermentation can be traced back to ancient civilizations. Yeast and mold are the fungi that are mostly used for fermentation, but at the University of Hohenheim our scientists prefer club fungi for the unique and distinct flavor they add to the fermented food. It is no longer a vegetable flavor but savory, or better: umami. The reasoning is that if plant-based food tastes nearly identical to (or even better than) animal-based food, then it might make more people change their eating habits and help ease the strain on our planet.

Gluten: The Texture Maestro

Student research at the University of Hohenheim has discovered that there are, so far, no vegan ham options on the market. In the true scientific spirit, they decided to find out why, and then began to produce the first “ham without oink” powered by the award- winning teaching program “Humboldt reloaded”. The University of Hohenheim's “Humboldt reloaded” program enables each of our students to immerse themselves in the world of research from their first year onwards.

Video: Ham Without Oink

Ham is a tricky kind of meat. It has a specific fibrous texture that anyone eating it will expect even from a substitute product. This texture is derived from the meats’ proteins themselves: Take out the meat from the ham, and it will lose its unique texture.

That’s where gluten comes in. Gluten is a vegetable structural protein with viscoelastic and adhesive properties. These are what ultimately lead to the favored chewiness of the food that it is part of. Too much gluten in your ham without oink will lead to a wheaty taste, too little will mean it doesn’t feel like ham in your mouth. Once you have these factors sorted out, there are still more specifically “hammy” things to think about: the juiciness, the salty taste, and the color.

Keep an eye out for the Hohenheim ham without oink in your favorite supermarket in the future!

Discover more about the Humboldt reloaded program and the current projects.

We still have to overcome many obstacles, but if we look at the speed of innovation everywhere, I am sure we will see all kinds of cultured meat products in supermarkets in the near future.

The Science of Steak: Inside the World of Cultured Meat Production

What do you want to have for dinner? Steak, chips, and beans? Check your app and press “prepare”. When you come home in the evening, all you have to do is take your dinner out of your printer-cooker.

Sounds like Star Trek? The University of Hohenheim's scientists say it might become reality in the next 10 years or so.

By then, more and more people will have a 3D-food-printer-cooker at home. In the supermarket we will buy cartridges containing nutrients that will enable the printer to cook your dinner according to your wishes or your dietary needs. You want more convenience? Buy a compound cartridge that holds everything you need for your favorite dinner. You want more sustainability? Feed food scraps to your printer-cooker.

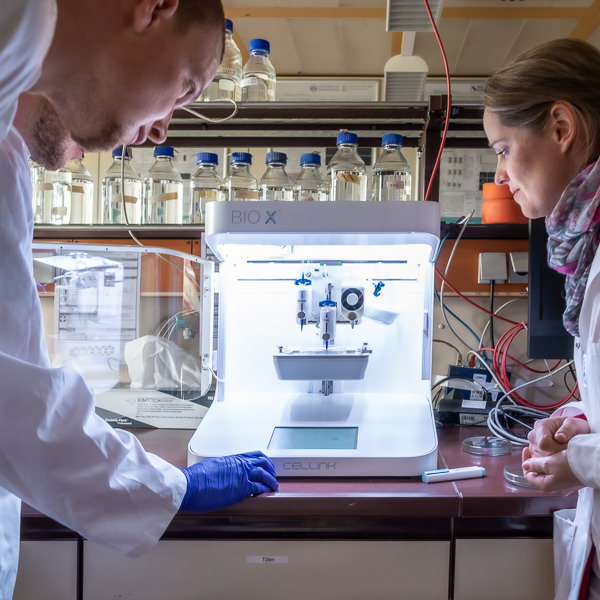

Is it still meat that your printer-cooker will prepare for you? Yes, it is, although not meat as we traditionally know it. It is not meat cut from a slaughtered animal, instead we take cells from an animal and let them grow outside it. The term for this is cultured meat.

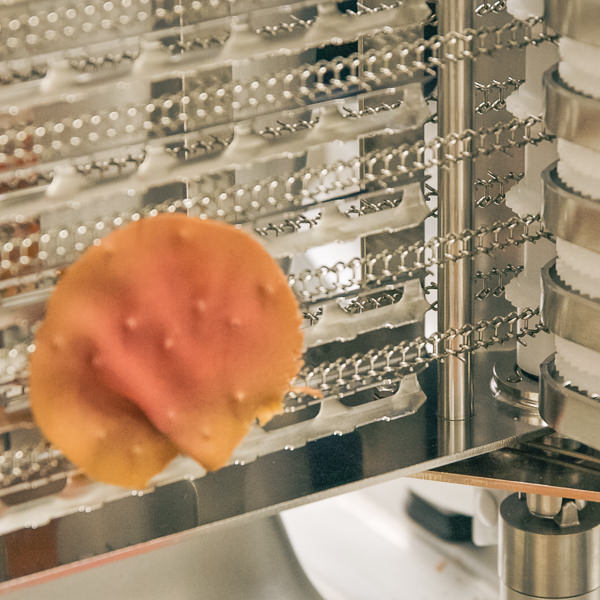

The processes of cultivating cultured meat are still very time consuming and expensive. After all, it's living cells we're talking about. They need all kinds of nutrients to grow and have plenty of processes to go through: cell isolation, cultivation, proliferation, differentiation, and agglomeration of 3-dimensional muscle and fat cells called meat spheroids. At last, the meat spheroids are ready for harvesting.

- In 2013, the Dutch scientist and cultured meat pioneer Mark Post publicly ate the first lab-grown burger in London during a press conference. The burger cost $330,000 and took 2 years to produce. Nowadays, the production costs for this burger are estimated at $10.

Watch video on YouTube - In 2020, Singapore was the first country in the world to allow the sale of cultured chicken meat. Production is time-consuming and expensive, that’s why the restaurant Huber’s Butchery offers just six servings on Thursdays only for about $18.50 per meal.

- Cultured meat is also known as lab-grown meat, cell-based meat, or clean meat.

So, let's boldly go where no meat has gone before and stay tuned for the next Star Trek adventure.

The project is sponsored by Avina foundation, Switzerland

Digging deeper

- AT Kearney expects alternative meats to make up 60 % market in 2040

- On a mission to create slaughter-free meat: Prof. Dr Mark Post on food grown from cells

- The State of Food Security and Nutrition in the World 2020

- The Future of Food and Agriculture - Alternative pathways to 2050

- Our World in Data

- Meat Substitute Market Size, Share & Trends Analysis Report By Source (Plant-based Protein, Mycoprotein, Soy-based)

- Heinrich Böll Stiftung: Der Fleischatlas 2021

Research with us

The University of Hohenheim is Germany’s leading research facility in agricultural research and food sciences, as well as strong and unparalleled in natural, social, and communication sciences.

- Researchers of Proven Excellence

Our scientists demonstrate exceptional skills, knowledge, and achievements. - Strong Focus on Research

We are very well networked and have a unique research profile. - Scientific Research facilities

The University of Hohenheim accommodates various institutions whose structures enable joint research and teaching activities, thus creating the optimal conditions for conducting outstanding research and then transferring it outside of the university. - Dedicated Portal for Early Career Researchers

We are strongly committed to qualification in the early stages of scientific careers. - Innovation and Transfer

We promote intensive cooperation between scientists, private companies, and other societal actors. - Scientific Integrity at the University of Hohenheim

The University of Hohenheim, as a center for research, teaching, and the promotion of early career researchers, undertakes to create and continuously develop the suitable framework conditions for anchoring the culture of scientific integrity and ethics in daily scientific practice. - Professorial Appointments

Our Professorial Appointment Portal offers help for all parties involved throughout the whole process of professorial appointments. - Cooperations

On all levels, the University of Hohenheim networks with universities and research institutions with outstanding international reputation. - Research Promotion

Professional and practical support and assistance through application processes for third-party funds.